Tube Bundle

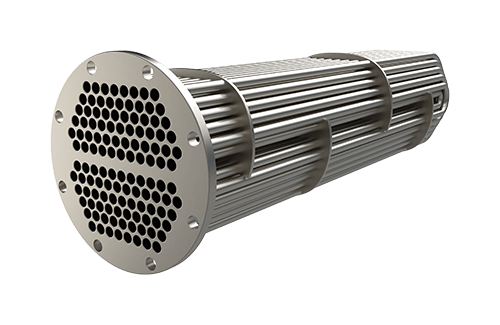

A Tube Bundle is a critical component of Shell & Tube Heat Exchangers, responsible for efficient thermal energy transfer between fluids. It consists of heat transfer tubes, tube sheets, baffles, tie rods, and spacers, ensuring optimal heat exchange efficiency and structural integrity.

At Rahavard Saei, we manufacture high-quality tube bundles using carbon steel, stainless steel, titanium, and nickel alloys, designed to withstand high temperatures, pressure fluctuations, and corrosive environments. Our designs comply with TEMA, API 660, and ASME Sec VIII standards, ensuring reliability and long service life.

Key Features & Benefits

- Optimized Heat Transfer – Engineered to enhance thermal exchange efficiency in various industrial applications

- Durable & High-Pressure Rated – Designed to operate in temperatures up to 1500°C and pressures up to 800 bar

- Precision Engineering – Manufactured to TEMA, API 660, and ASME Sec VIII standards for mechanical reliability

- Material Flexibility – Available in carbon steel, stainless steel, titanium, and nickel alloys for corrosion resistance

- Custom Fabrication – Tailored to specific process requirements, including fluid type, flow rate, and pressure conditions

Mechanisms and Diverse Applications

Industries

Marine & Offshore

Corrosion-resistant solutions for ship engine cooling and seawater applications

Chemical Processing

Ensuring safe and efficient heat transfer for reactive fluids

Food & Beverage

Used in pasteurization, sterilization, and temperature control applications

Power Generation

Optimizing steam generation and waste heat recovery

Oil & Gas

Enhancing heat recovery and cooling efficiency in petrochemical processing

How It Works

The Tube Bundle consists of multiple tubes housed within the shell of a heat exchanger, allowing two separate fluids to exchange heat efficiently. The design and configuration of the tube bundle depend on process conditions such as fluid type, temperature, and pressure requirements.

Key Components & Functions

- Heat Transfer Tubes – The primary medium for heat exchange, allowing hot and cold fluids to flow separately.

- Tube Sheets – Provide structural support and secure the tubes in place, preventing leaks between fluid paths.

- Baffles – Direct the shell-side fluid flow to increase turbulence and improve heat transfer efficiency.

- Tie Rods & Spacers – Maintain proper spacing and alignment of tubes, ensuring mechanical stability.

- Impingement Plates – Protect tubes from fluid erosion at high velocities, extending service life.

During operation, the hot fluid flows inside the tubes, while the cooling fluid moves through the shell side. The baffles force the cooling fluid into a controlled flow pattern, improving thermal contact with the tubes and maximizing efficiency. Proper material selection ensures resistance to corrosion, scaling, and mechanical wear, reducing maintenance needs and extending operational life

Ready to Order? Get in Touch Today!

Looking for the right product for your needs? Get expert guidance and a customized quote by reaching out to us: