Gasketed Plate Heat Exchanger

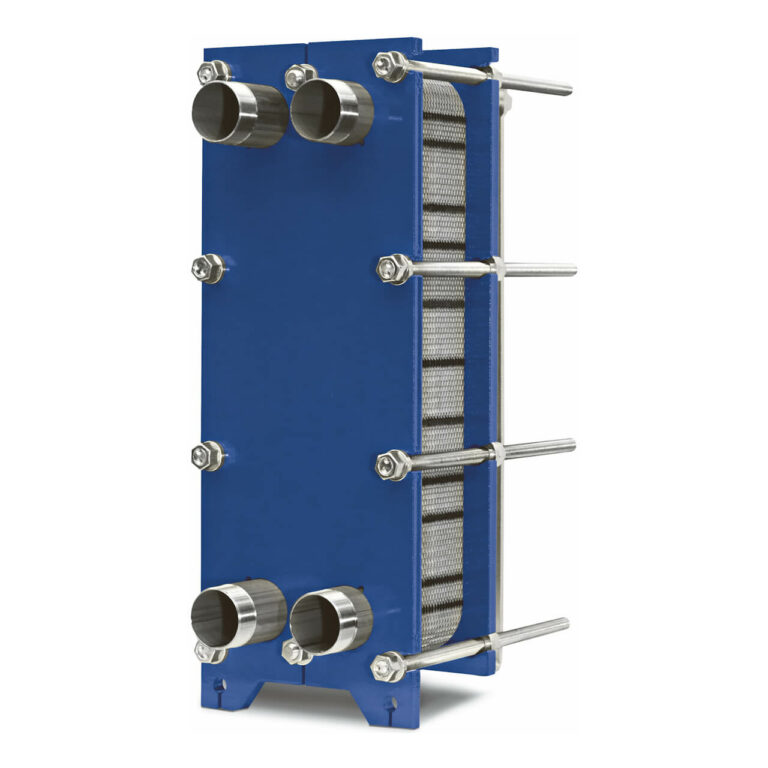

A Gasketed Plate Heat Exchanger (GPHE) is a highly efficient and modular heat transfer system, designed to provide optimized thermal exchange in various industrial applications. The unit consists of thin, corrugated metal plates, which are stacked together with elastomer gaskets to create alternating hot and cold fluid channels. This design ensures maximum heat transfer efficiency while maintaining easy access for maintenance and cleaning.

At Rahavard Saei, we manufacture high-performance Gasketed Plate Heat Exchangers using stainless steel, titanium, and nickel alloys, engineered to API 662 and ASME Sec VIII standards. Our GPHEs are designed for high efficiency, durability, and ease of maintenance, making them ideal for industries requiring precise temperature control and minimal energy loss.

Key Features & Benefits

- Superior Heat Transfer Efficiency – Corrugated plate design increases turbulence and thermal performance

- Easy Maintenance & Cleaning – Plates can be easily removed, cleaned, or replaced, ensuring minimal downtime

- Flexible & Scalable Design – The number of plates can be adjusted based on process requirements

- Durable & High-Pressure Rated – Operates at pressures up to 25 bar and temperatures up to 200°C

- Corrosion-Resistant Materials – Manufactured using stainless steel, titanium, and nickel alloys for enhanced durability

- Leak-Proof Sealing – Uses NBR, EPDM, HNBR, Silicone, and Viton gaskets to prevent fluid leakage

Mechanisms and Diverse Applications

Industries

Oil & Gas

Enhancing heat recovery and efficiency in petrochemical plants

Chemical & Petrochemical

Ensuring safe and precise thermal control for sensitive processes

Food & Beverage

Used for pasteurization, sterilization, and temperature control

Power & Energy

Optimizing cooling systems and heat recovery applications

Marine & Offshore

Providing compact and corrosion-resistant heat exchange solutions for ships and offshore platforms

How It Works

A Gasketed Plate Heat Exchanger consists of a series of corrugated metal plates, stacked between a fixed and a movable frame, with gaskets ensuring a leak-proof seal. These plates create alternating hot and cold fluid channels, enabling efficient heat transfer without direct mixing of the fluids.

Key Components & Functions

- Fixed Frame Plate – Holds the plate assembly in place and provides structural support.

- Movable Frame Plate – Allows for easy disassembly and maintenance.

- Heat Transfer Plates – Thin, metal plates with a corrugated surface, maximizing fluid turbulence and heat exchange efficiency.

- Sealing Gaskets – Prevent fluid leakage while directing the hot and cold flows in alternating channels.

- Tightening Bolts – Secure the frame and plates together, ensuring optimal pressure distribution.

- Guide Rails – Align the plates correctly for uniform fluid distribution.

During operation, two separate fluids enter the heat exchanger through inlet nozzles, flowing between the alternating hot and cold channels. The corrugated plate surfaces create turbulence, which increases heat transfer efficiency while reducing fouling and scaling. The gasket system ensures complete fluid separation, preventing contamination between the two streams.

This compact and modular design allows for quick adjustments, easy maintenance, and high thermal efficiency, making it ideal for industries requiring cost-effective and energy-efficient heat exchange solutions.

Ready to Order? Get in Touch Today!

Looking for the right product for your needs? Get expert guidance and a customized quote by reaching out to us: